Factory Environment

Production Workshop

Sewing Workshop

R & D Center

Production Line

Cutting Workshop

Shoes Material Warehouse

Shoe Last Research Center

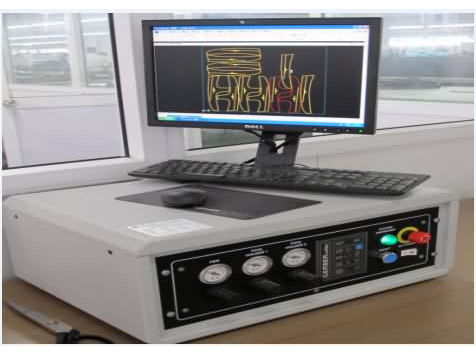

Testing Center

Manufacturing Process

1..All material QA quality check system before production

2.Cutting department, cut raw material according to shoes design

3.Shoe upper stiching and making system

4.Button making

5.Toe and back lasting

6.Outsole PU injection

7.Products Packing

Raw Materials

1. Embossed/Thickened suede/Corrected/Full grain/Smooth cow leather

2. Litchi style embossed/soft/cow leather

3. Imported nubuck/soft surface/thickened suede leather

4. Thickened suede leather, thickened suede leather +waterproof nylon cloth,

5. Full grain leather, Frosted leather, Oily crazy horse leather, PVC, Rubber, PU, etc.

Technical Support

Quality Control

As a professional safety shoes manufacturer, we have the necessary test equipment, such as: safety shoe wear tester, impact resistance tester, safety shoe folding tester, safety shoe compression pierced tester.

Products Warranty

All our products are offered 8 month quality warranty after shipping. If the shoes are broken within 8 month, please contact our salesman, and we will compensate u new shoes without any payment.

Returns & Exchange Policy

All our products are offered 8 month quality warranty after shipping. If the shoes are broken within 8 month, please contact our salesman, and we will compensate u new shoes without any payment.